The history of Uusimäen Konepaja Ky

Eero Uusimäki, the founder of the company

12.01.1926 - 06.09.2016 A strange light phenomenon appeared in Lappajärvi in 1953. A blue light wedge split a dark waking village. From chinks of their curtains, peepers saw how the smoking light was flashing in the windows and in the chink of the door of the workshop of the blacksmith Eero. Ignorant thought that some bad accident had happened but over the day became clear that Eero Uusimäki had acquired a welding device for his workshop. Eero bought the transformer in the neighbour parish. The device was a "self-made" prototype, which a skilful Eero developed by building a controller in the ground wire, which allowed doing more versatile welding works. The same device served for a long time and it also was used for melting of frozen water pipes all around the county. Practically melting was heating the metal pipes by leading electricity through them. Those were the times when water pipes were mostly made of metal. Since, there was no electric power in every house at that time so electricity was "borrowed" by power cables, which were raised onto the nearest open air-cables by a long stick with an iron hook, so electricity was obtained to the machine. The local electricity company which still functions, Vimpelin Voima Oy, did not consider this as anyhow bad matter. The main thing was that water flowed in pipes also in cold winters.

On the stage of the entrepreneur of the metal field, 1949 many kind of knowledge was needed so Eero first studied in the "home-industry-school" in Äänekoski and after that in the "blacksmith school" in Ypäjä. Eero acted as the blacksmith in Jalasjärvi and Lapua after graduating his both schools as a head of the class with their praiseworthy degrees, until he built, with his own allowances when banks did not grant a loan for a "too poor customer", his first own workshop in his home yard.

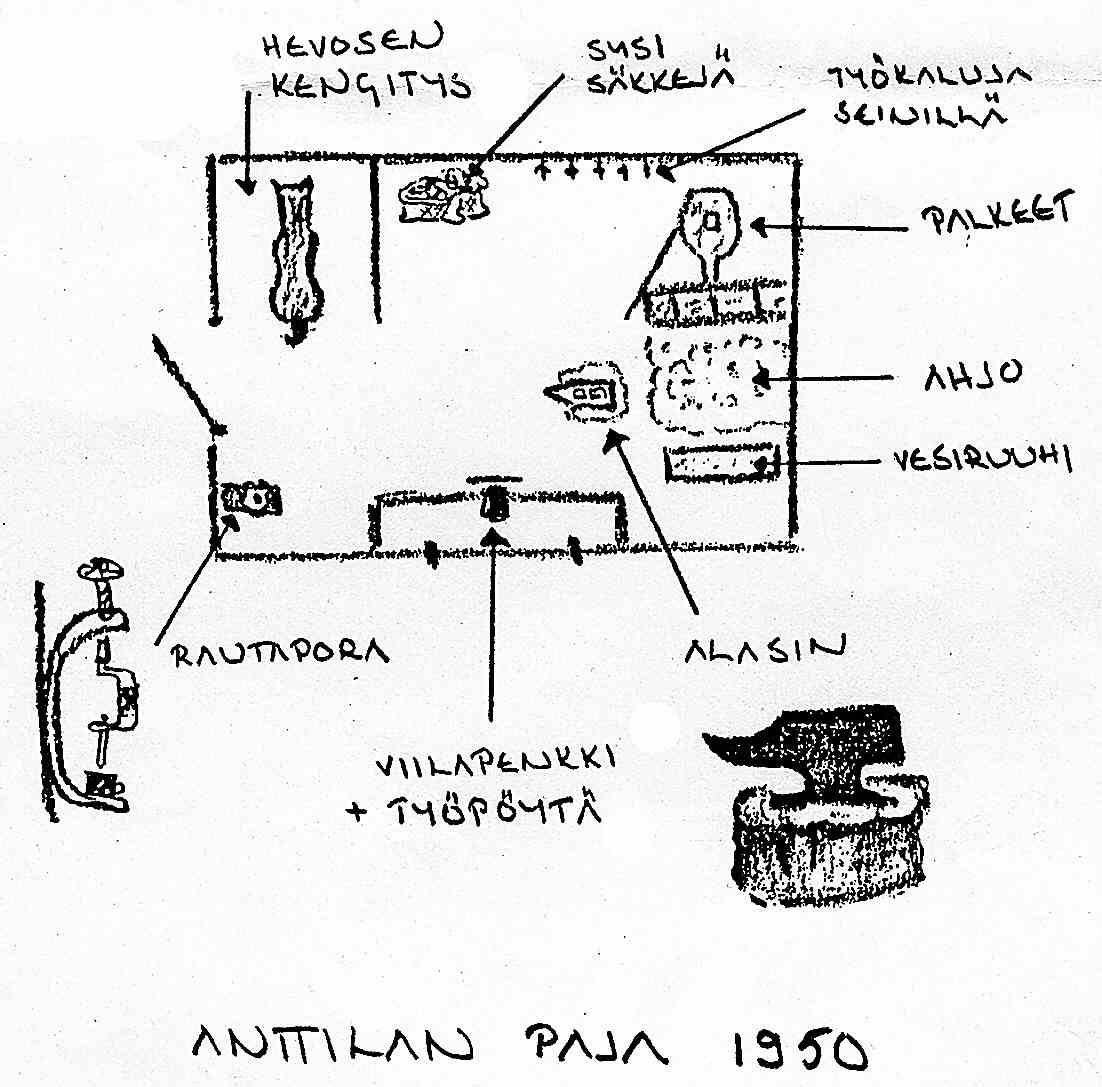

- "In the beginning I started shoeing horses, ironing sleighs and doing all kind of blacksmith work. The timbered workshop was quite elementary, but at least an "umbrella", the leaking skin bellows, file bench and anvil were yet in the forge. Fortunately, I made tongs and other craft tools at school and plenty of them are still working. My workshop got the villagers' popularity, the horses came also from the neighbour parishes. I operated for about two years in this workshop earning, among others, my first engagement rings", Eero Uusimäki remembers.

Countryside and agriculture changed from a horse equipment, stubble ploughs and wooden harrows fast at that time, to a Valmet 15, "Grey-Fergusson" and Zetor tractors, so the workshop also had to be developed. Eero acquired a grinding machine and an electric fan to the forge. Eero built himself a machine hammer. Eero's grandfather predicted that it will be a dud of three hundred Finnish marks. That was the price of the bought parts of the hammer. That hammer did not become a dud but served for decades as a "factory" of province famous plough dowels. Nowadays that machine hammer is not anymore in the production use but still operates as the forge, too! By the way, Eero made those plough dowels totally sign-specifically with the help of the diagrams developed by himself. The ploughs themselves did not need to be delivered to the workshop. Accordingly, to the same principle, JAKE products also are delivered so probably there is some "family fault"...

Then the old timber workshop became small and a new 10x15 m brick hall rose with the help of the assistance decision of Trade- and Industry Ministry, signed by the corresponding minister Ahti Karjalainen in 1960. Uusimäen Korjaamo became the name of the company. That same brick hall served as the paint shop of JAKE up to the beginning of the year 2005 and the workshop equipment are still there in working order, also the forge and the machine hammer.

1960 built brick hall. Let it further be noted that, for example,

Eero spaded the basis of this building by a shovel and crowbar. And the ground was and still is, very very rocky...

Forge and anvil

The horror of today's work safety authorities:

mechanical pressing device without any guards. Eero remembers more: - "I acquired more machines. We made and repaired agriculture machines, tractor trailers and sleighs. The bookkeeping and the receipts came along to the picture as first employed workers, too. We began maintenance work, repairs and painting work of cars. As well we got subcontracting, among others, from Uno Wikar & Co (later Oy Wikar Ab / Kronos) and from the Pietarsaari factories of Wärtsilä (later NokkaTume Oy)".

After 15 years the premises became small again and Eero decided to extend still once when his own boys were also interested in the field. The modern industrial hall with its social premises, offices and new machines was created. When Eero's age of retirement approached after a few years, the change of generation began: the company form became a limited partnership company through the partnership firm and Uusimäen Konepaja Ky was born.

- "This way the generation changed and ended as an entrepreneur of the metal field of my long and eventful life-work which had lasted four decades. I hope that the boys also are continuing at similar relentless toughness as I have done. I also am grateful for the fact that I have been allowed to be totally healthy during my whole life", Eero says.

I (the writer) myself have been often asked how long "the old master" further led the company also after retiring, as perhaps the situation quite often after the change of generation is. The answer in our case is: not even one day! Eero followed from the sidelines genuinely interested and let us boys make our own decisions.

During his pension days, Eero Uusimäki extended his perspective to a life and world by travelling and by following the progress of the development tightly. The vantage point was near when the boys continued work and developed the company into the modern company of the metal industry with their own products on the shade of which so important subcontracting stayed during their own period.

Lappajärvi, January 2006. |